SMD Holding Device (December 2024)

Surface Mounted Devices (SMD) are very common nowadays and many circuits are available only as SMD packages.

One

may find difficult to keep these tiny components in place during

soldering : until recently I used the classic "tweezers method" to hold

the SMD on the Printed Circuit Board (PCB) while soldering it.

In

order to simplify the procedure when a large number of SMDs must be

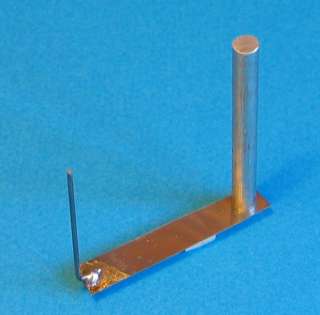

soldered on a board, I designed a "holding device" built

from components and materials available in my junk box : the

result is shown below (click on the pictures to enlarge) :

The

PCB is kept in position on the lower white plate by the left and

right fingers and the SMD is held in place by the pressure of the

central tool. The three black circles (small rubber feet glued on the

plate) prevent the PCB from sliding when you solder the SMD on

it.

1. Building the tool.

1/ The lower plate is a piece

of wood or chipboard (15 x 12 cm) in which I drilled three holes, two

for the left and right fingers and one for the central SMD holding tool.

2/ The fingers

are made of copper strips soldered at the end of banana plugs. The

small rubber disks glued to the strip's ends help to keep the PCB in

position.

3/ The SMD holding tool

is based on a 5 cm length of an old potentiometer shaft : a strip of

flexible steel is fastened to one end of it, and a 4 cm length of

steel wire (the "Music wire" used by aeromodellers) is soldered

to the other end of this strip.

I gently polished the end of this steel wire with fine-grain

sandpaper in order it doesn't mark the SMD when it is pressed on.

2. Using the tool.

A

picture being worth a thousand words, have a look at the photo below

showing a 14-pin SOIC-14 SMD component kept in place before

soldering.

Conclusion.

Built in no time, this little device can be a great help when you solder many SMDs on a PCB.

Home