The story.

The first step was to get the PCB : I sent an Email to Ivan Makarov VE3IVM

who designed a PCB including the N2PK modifications for dual fast

ADCs. A few days later, I received an envelope with three

beautiful PCBs (the VNA and two coupler boards).

I

then ordered the Valpey-Fisher oscillator to Eugene Skopal AE2F

and most of the passive and active components to Digikey.

I was now ready to build the VNA.

As components

are SMDs, one must be careful when soldering them on the board : I

used the SMD Holding Device described elsewhere in my Web pages and, to mitigate mistakes, I double checked each component before soldering it.

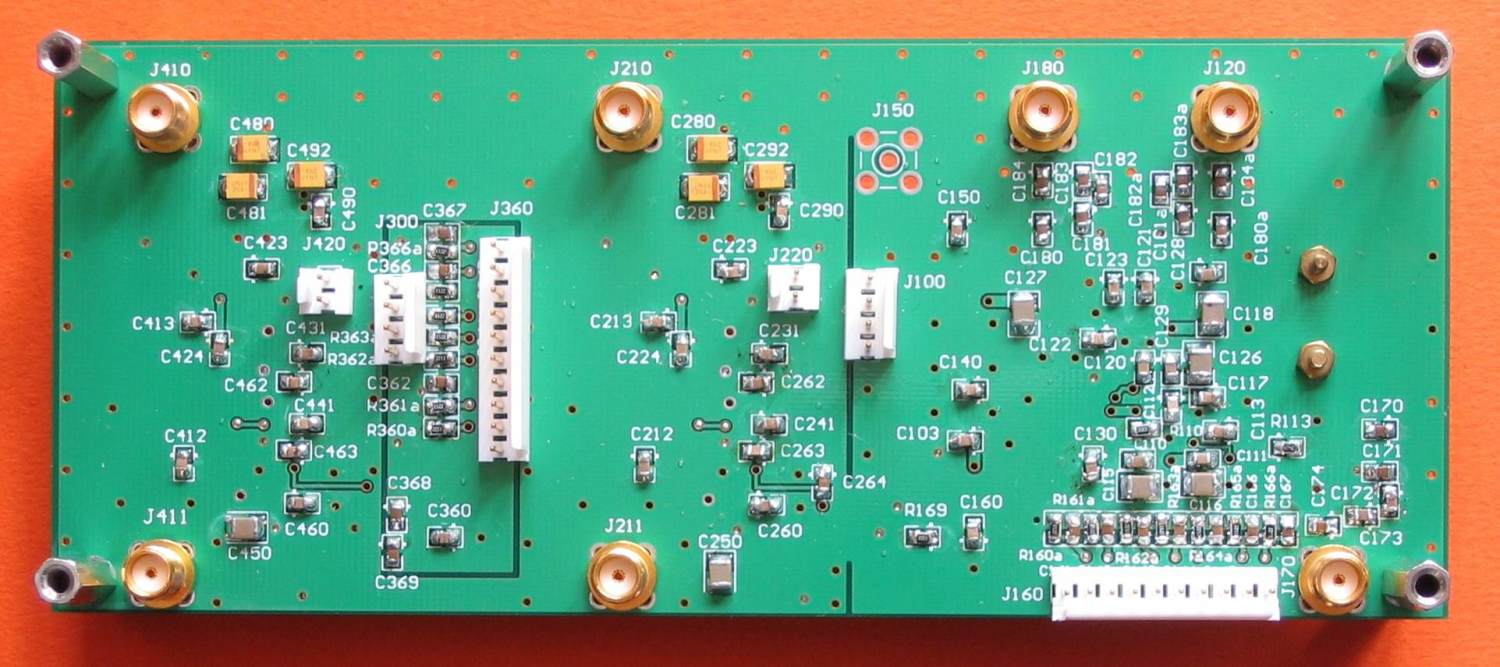

In a short time, the main board was ready and checked. Both sides of the populated PCB are shown below (click on the pictures to enlarge) :

I then designed a power supply around a DATEL DC/DC converter : this converter is oversized (5 V @ 3 A and 12 V @ 500 mA) for sure,

but it was in my junk box! A long time burn-in was then

performed, the power supply outputs being connected to wire wound

resistors : during this test, I periodically checked the DC output

voltages and watched the noise levels present on these lines.

Measured overall efficiency was around 80%.

After that, I put the VNA, the power supply and the connectors up on a temporary plywood base, in order to make measurements easier during the first tests.

Well, everything was now ready for the smoke test!

I

carefully followed the N2PK's and VE3IVM's advice, checking voltages on

several test points of the VNA board, and was very pleased to

read nominal values everywhere.

After connecting the VNA to the parallel port of my PC, I ran one of the N2PK debug programs and was able to talk to the VNA!

Now,

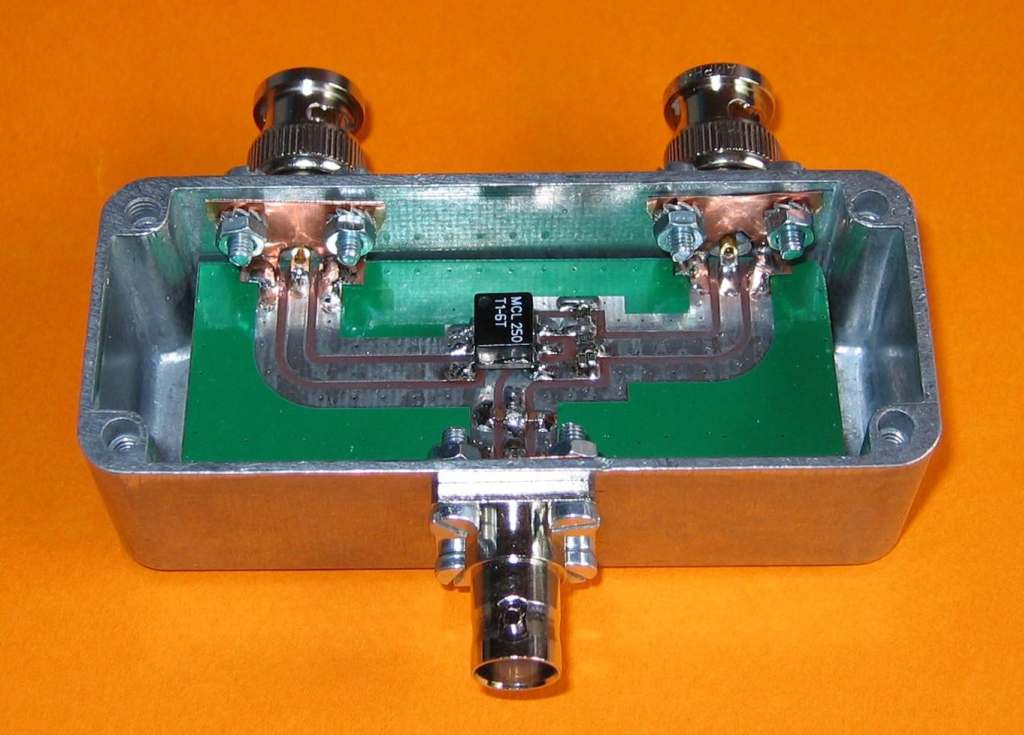

it was time to build the BNC Open and Short calibration standards,

and the T1-6T reflexion bridge on one the two boards provided by

VE3IVM : this coupler is shown below.

Tests

of the VNA associated with the coupler, on several known loads, were

then successfully conducted, and results were in good agreement with

values measured with an HP analyzer.

Before

installing my VNA in a convenient enclosure, I fastened a home made

heatsink over the DDSs and the time base, using the two holes intended

for that purpose on the PCB . I was greatly inspired by the VE3FJ

method.

The

enclosure for this equipment is a metal box I had in my junk box : the

pictures below shows that this new job suits it perfectly.

Top view

Front panel with the T1-6T coupler

Rear panel

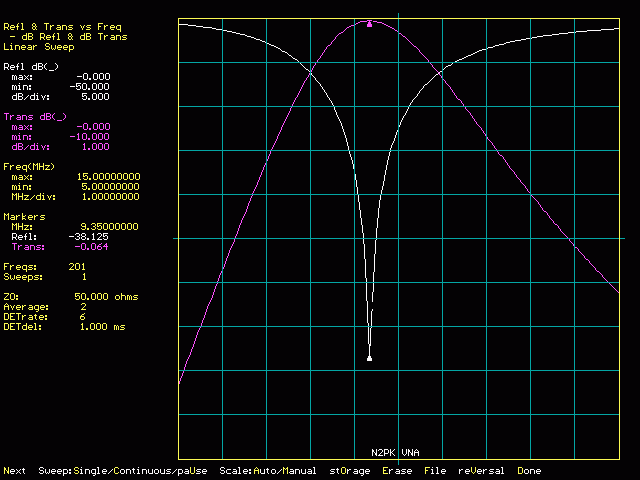

Here is a sample picture of measurement carried out on a simple RLC circuit resonating around 9 MHz (N2PK software) :

Conclusion.

This is the end of the building phase and the beginning of other adventures in the world of impedance measurement.

I want to sincerely thank Paul N2PK, Ivan VE3IVM and all people involved in the development of this project (software as well as hardware).Congratulations to all!